In-house construction team.

The construction of Concerto will be carried out by our in-house construction team. This vertical integration empowers us to cross-innovate between design and construction. Any R&D carried out by our construction team is brought to the table during the design phase, enabling us to incorporate new workflows and practices that will speed up and enhance quality across the construction process.

collocated construction yard.

The benefits of manufacturing all pre-engineered components on site are endless. It reduces our reliance on road transport and helps us deliver the project on time.

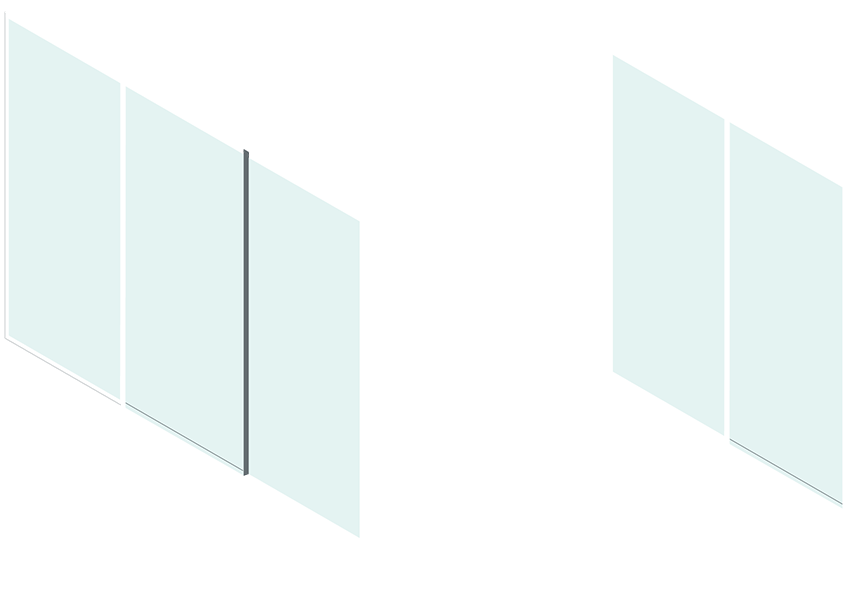

Optimised construction equipment.

Customised shuttering sheets made specifically to cater to Concerto's grid will speed up construction and ensure a smooth finish on all concrete structures.

We have invested in Custom Jack Poles that can extend to lengths beyond the industry standard. This need-based investment was required to meet the construction requirements of the basement at Concerto which is taller than most basements.

Captive power.

The construction process is 100% non reliant on the power grid. Captive power generated on site will reduce the downtime that often occurs when connected to the grid.

Proximity to RMC plants.

Concerto is located approximately 1km away from 2 of the industries leading concrete plants. This reduces our logistical requirements drastically as well as shortens transportation time.